with the Balanset-1A Device

Preparing the Necessary Tools

- vibration sensors, optical speed sensor, magnetic base, software package, and included accessories.

- Connect the device to your PC using the USB interface and confirm the software installation.

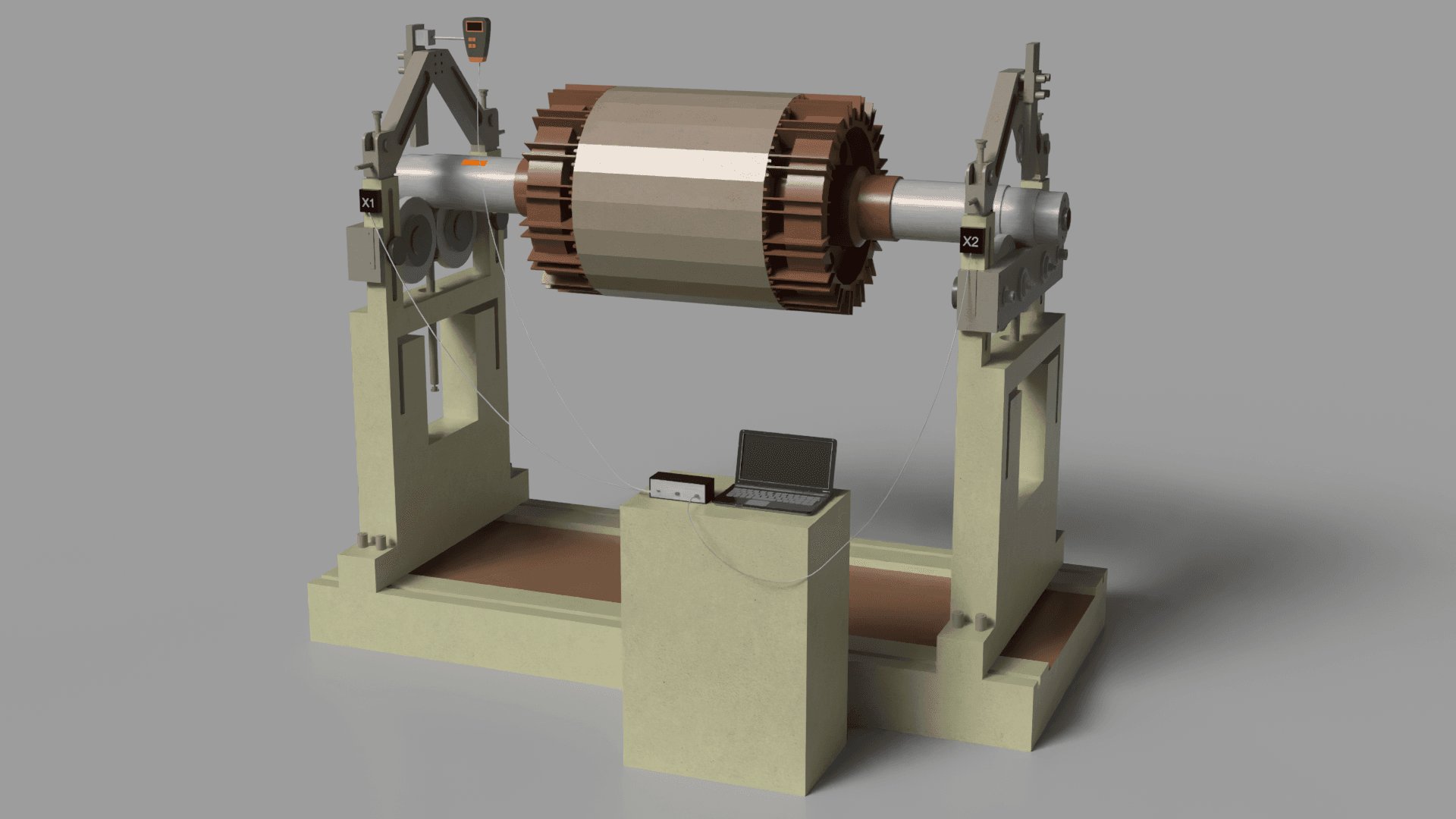

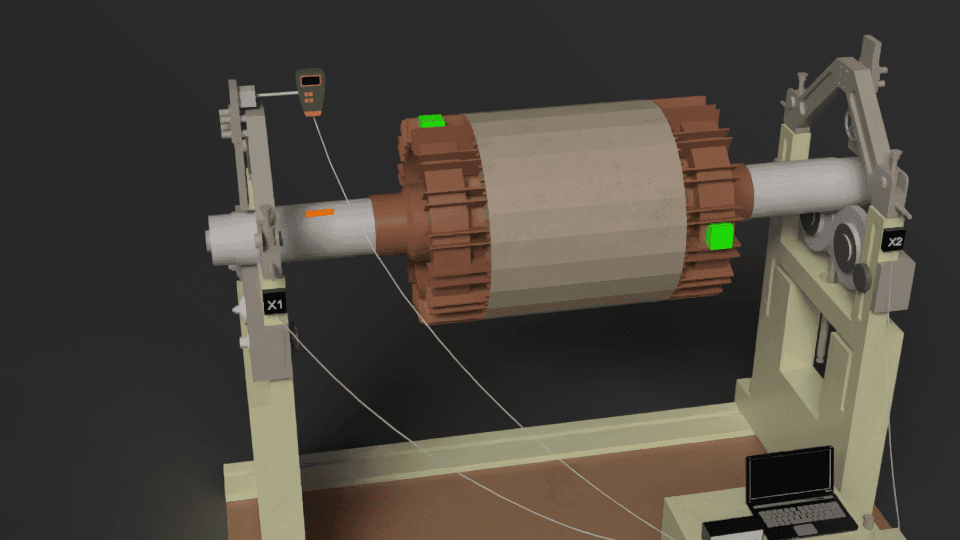

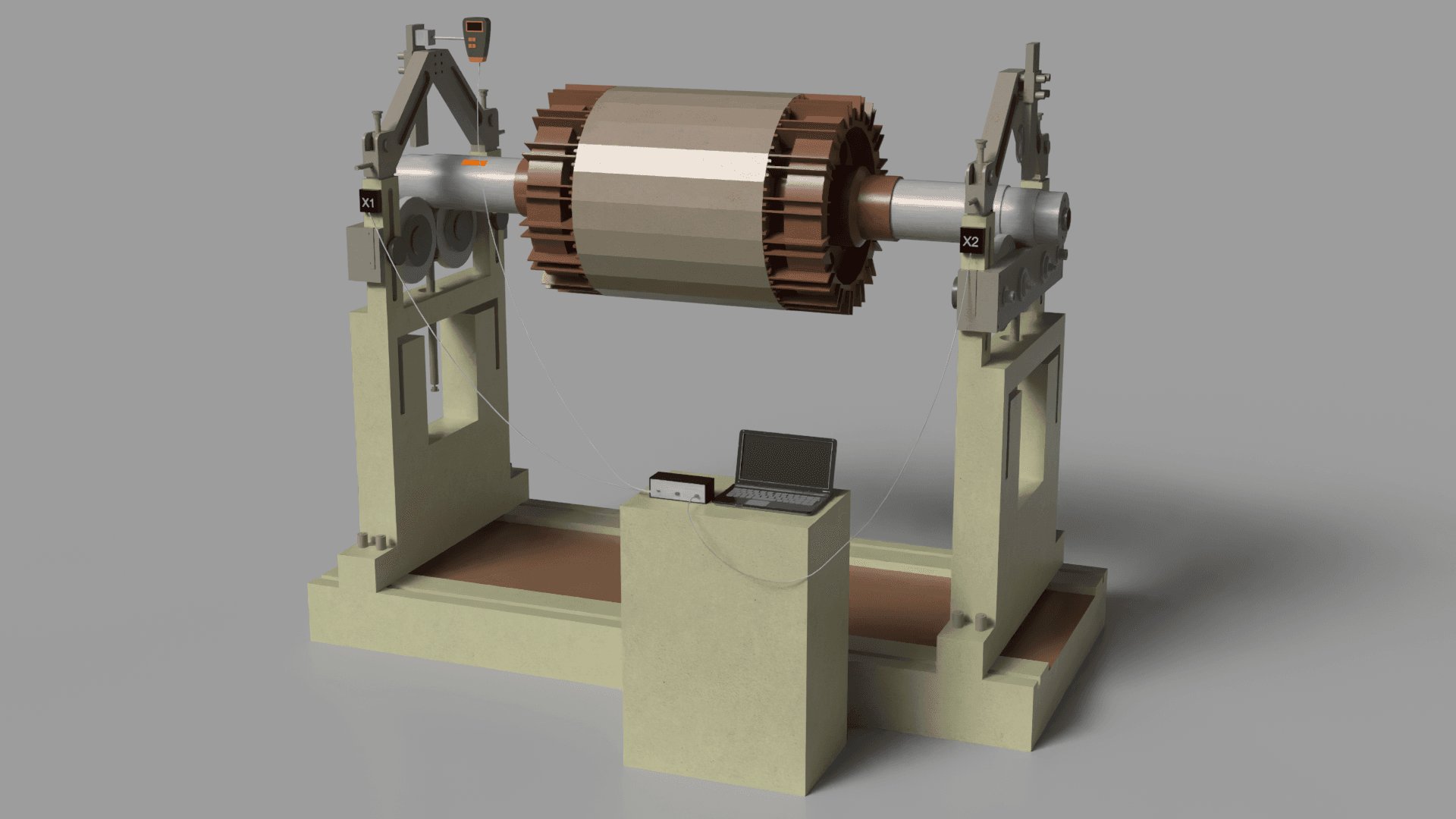

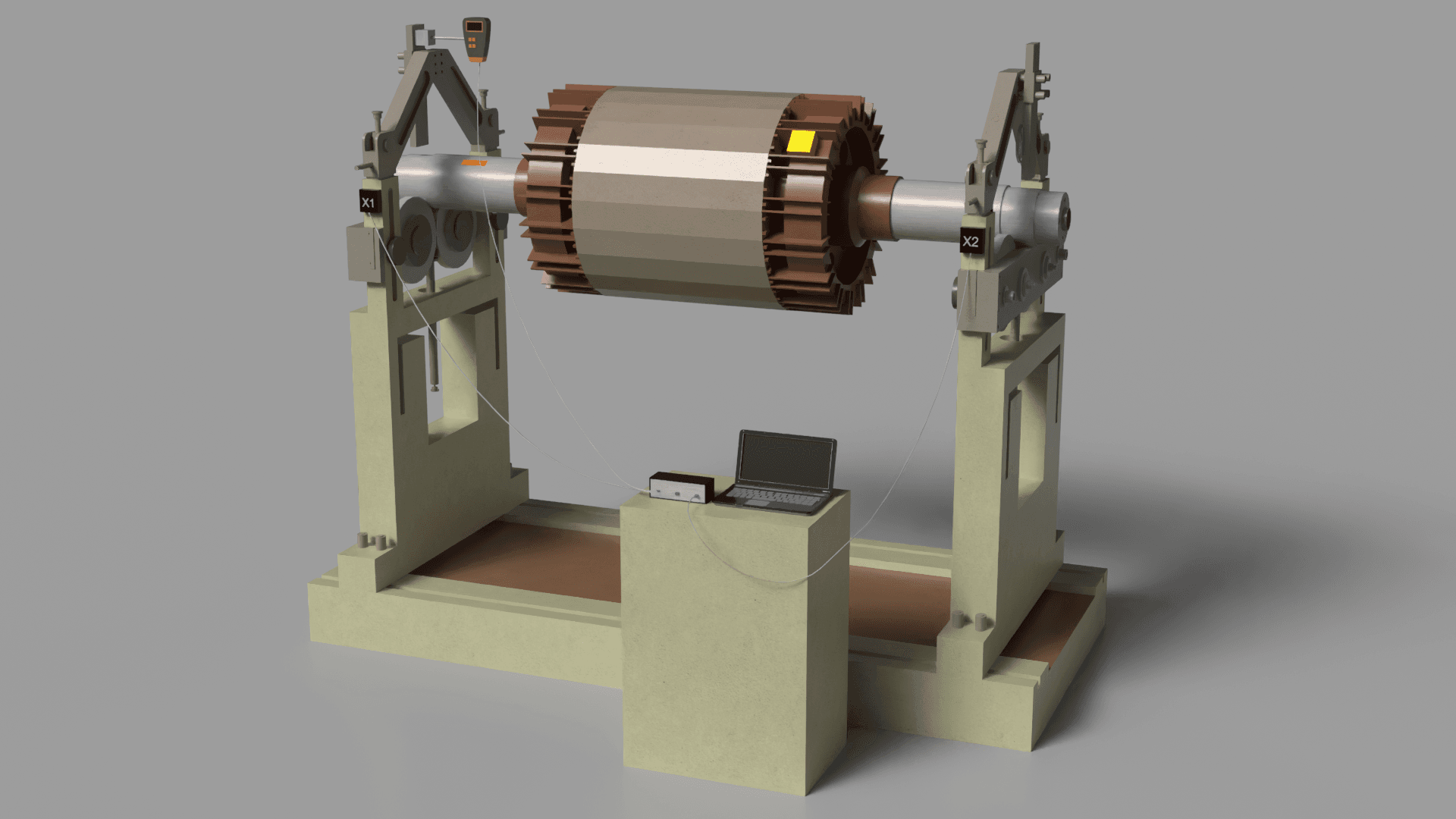

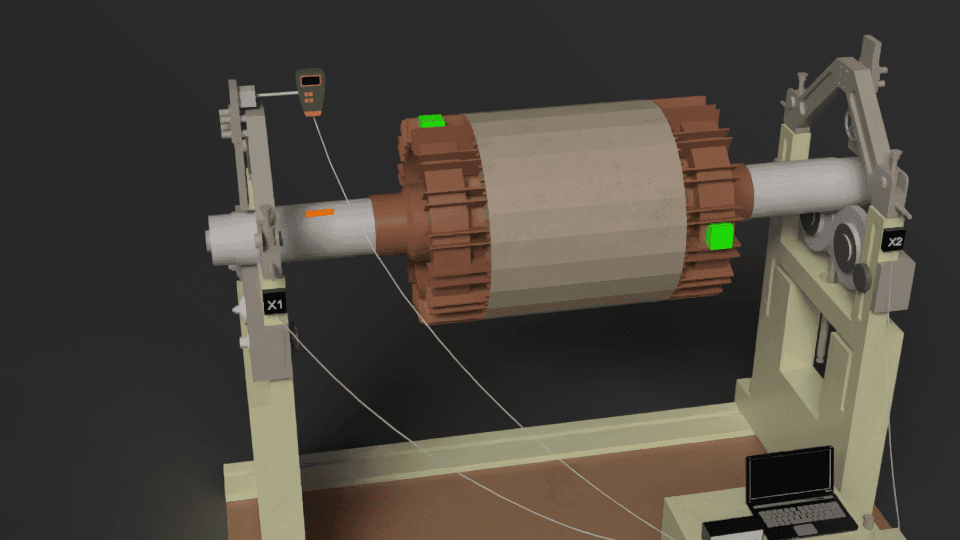

Sensor Installation

- Attach the vibration sensors firmly to the machine casing in areas with the highest vibration amplitude, usually close to the bearing supports.

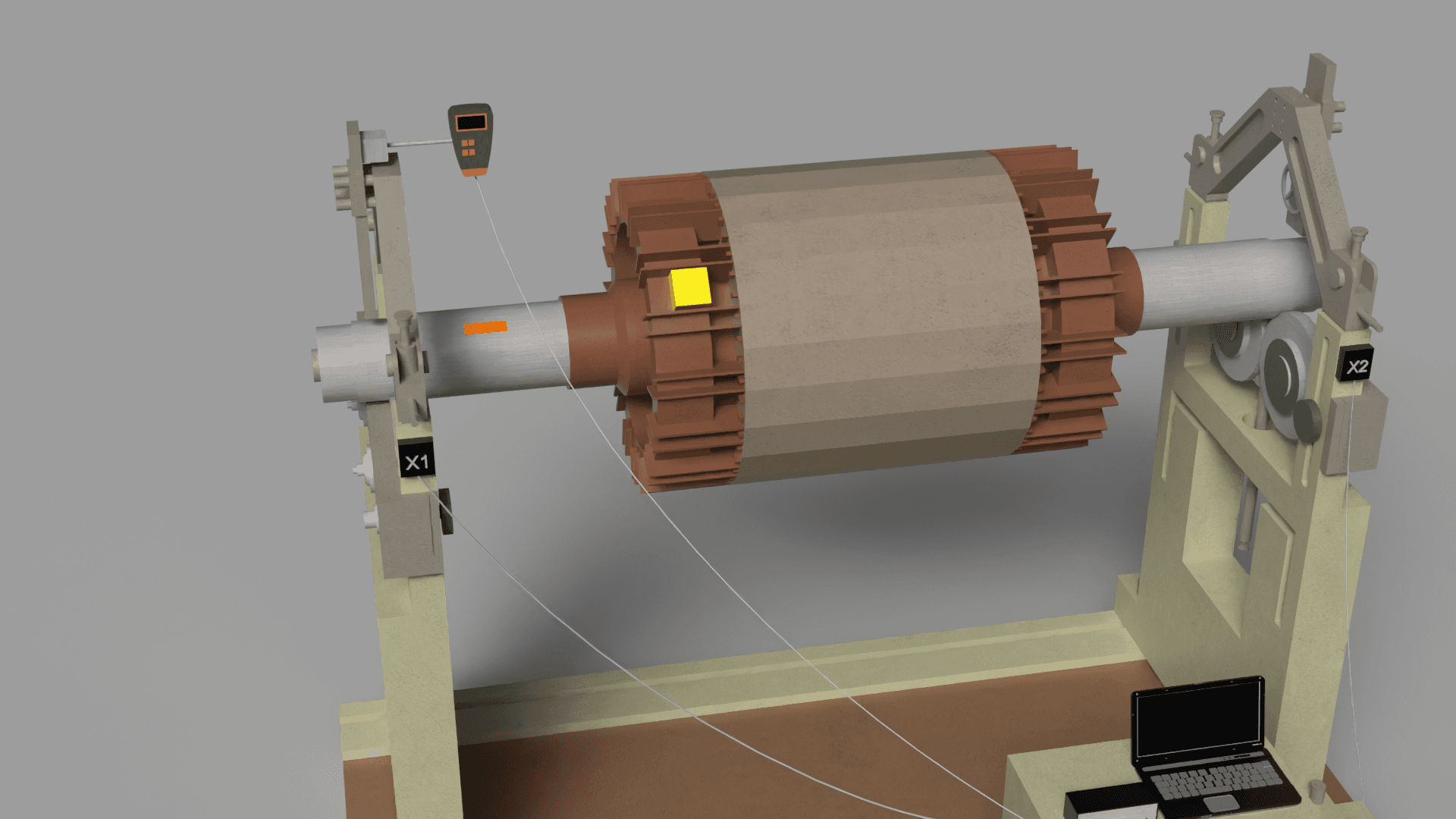

- Direct the laser speed sensor towards the rotor and affix reflective tape to the rotor surface to facilitate phase angle measurement.

Launching the Software

- Launch the Balanset software on your computer.

- Configure the software for either single-plane or two-plane balancing, based on the rotor's characteristics and the desired outcome.

- Bring the rotor to its normal operating rotational frequency.

- The application will acquire data on vibration magnitude, rotational velocity, and phase angle to determine the initial imbalance state.

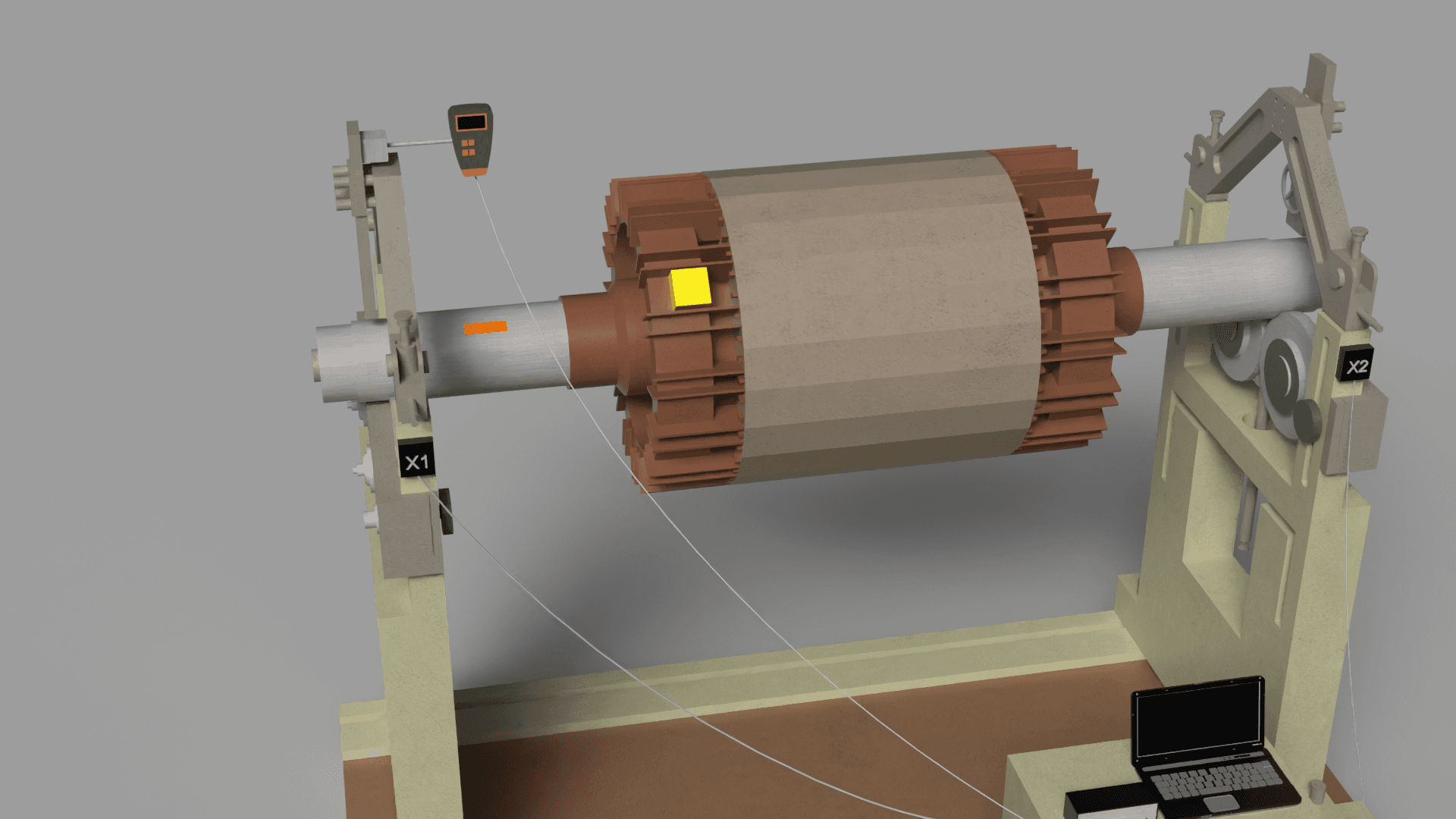

Attaching the Trial Weight

- Halt the rotation and mount a test weight at a designated position on the rotor, with the weight's value entered into the software (usually in grams).

- Restart the rotor, and the software will record the changes in vibration level and phase angle.

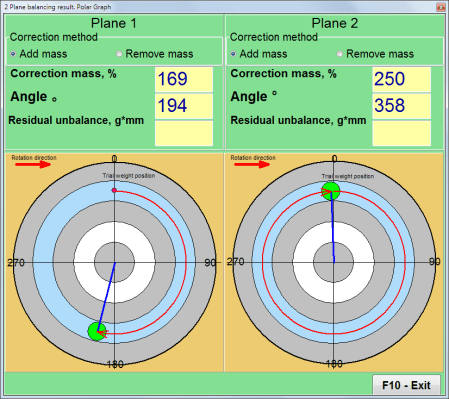

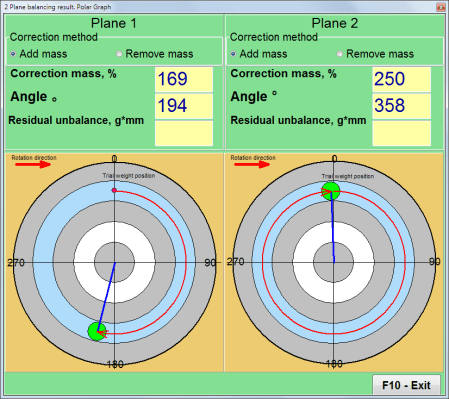

Determining the Corrective Mass

- Based on the measured data, the software automatically calculates the correction weight parameters: mass and installation angle.

- The results of the calculation are shown both numerically and visually through charts and graphs.

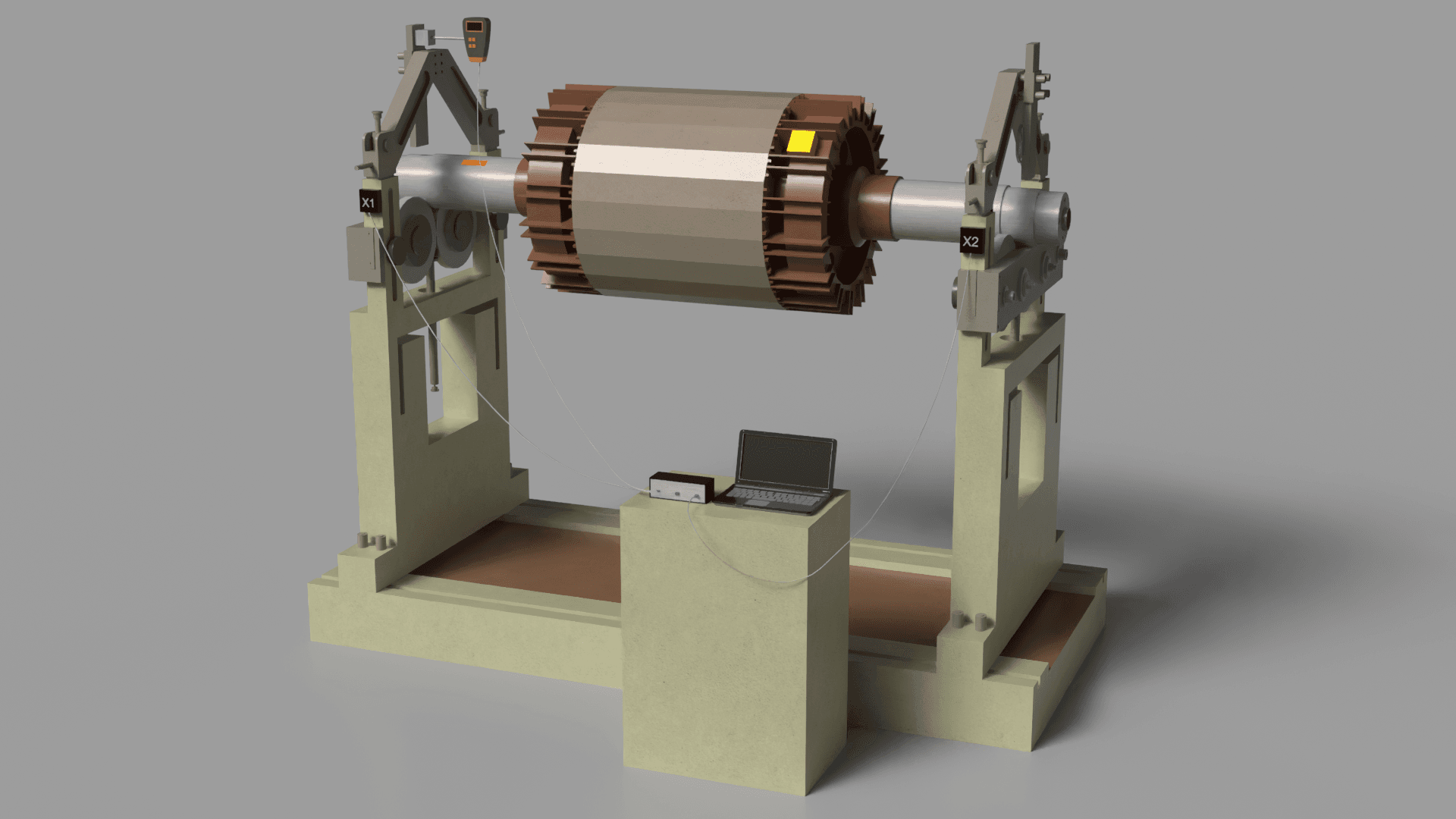

Mounting the Compensating Weight

- Attach the computed compensating weight to the rotor as indicated by the software's output.

- If necessary, perform intermediate checks to verify that the imbalance is being reduced.

Final Check and Balance Confirmation

- Once the corrective weight is in place, restart the rotor and measure the remaining vibration amplitude.

- If the measured vibration falls within the tolerance defined by ISO 1940, the balancing process is considered successful.

- Should the vibration still be excessive, repeat the balancing steps, making further adjustments to the corrective weight as needed.

Generating a Documentation of the Balancing Results

- All balancing results are logged and archived within the software, from which you can produce a printable report summarizing the vibration levels, compensating weight, and its installation position.

Final Recommendations

- Verify the secure attachment of all balancing weights and measurement sensors.

- Check that the rotor's rotation is smooth and free from undue noise or vibration.

- In cases where the rotor is integrated into a more complex system, ensure the correct operation and interaction of all related components.

By implementing this method, you can effectively eliminate imbalance, reduce vibration levels, and increase the lifespan of the machinery.

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL

Our website about Beater balancing

Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal

Facebook: https://www.facebook.com/marketplace/item/350151228150722

http://xn--e1akngbj.xn----7sbwjfcr8bzb0b.xn--p1ai/index.php?title=Fan_Balancing_Machine